| History | Videos and TV contributions |

| History of CI in Hamm | Newspaper clippings |

| Fort St. Vrain - The HTR prototype | Books on the topic |

Fort St Vrain

The HTR prototype in the USA was already a bankrupt reactor

***

The Documents of the failure from 1985 accessible again:

The operators of HTR's forerunner Fort St. Vrain in the USA report problems and breakdowns

The USA wants to do more research in the field of high-temperature reactors. We take this as an opportunity to address the previous bad experiences with the American precursor reactor of the HTR line in Fort St. Vrain and then document an original document from the operator at that time from 1985, which was previously inaccessible to the public, showing many problems and breakdowns during its Operating time can be added.

For two years it has become increasingly clear that the HTR no longer has a future in South Africa. The Pebble Bed Modular Reactor company had to lay off around 800 of its 2010 employees in March 600 because the South African state no longer gave any grants for the project, which was in a whirlwind. The PBMR managers have been looking intensively for new donors for months.

*

Full screen version of the map of the nuclear world - Fort St Vrain, ColoradoUS

*

Will Obama save the THTR?

In March 2010, it was announced that the US Department of Energy is donating $ 10 million to the PBMR company so that it can survive the next few months and keep operations up to date.

Despite this (relatively small) injection of funds, it is very likely that under these circumstances the PBMR can only be further developed in the USA. As early as January 2009, the radioactive spherical fuel elements manufactured in South Africa with the help of German companies were silently shipped to the USA. According to South African media reports, a new PBMR could be expected to go into operation in the USA in 2024. The US government has now approved two groups with a total of 40 participants to deal with the topic in more detail (1).

It would certainly be appropriate for US energy policy makers to finally grapple with the disastrous experiences of their own "archaic" predecessors of the PBMR, Peach Bottom-1 and Fort St. Vrain. But there can be no question of that. On February 16, 2010, US President Obama announced that, after a long period of time, he would again provide state loans for nuclear power plants and step up into nuclear research.

The USA has been a member of the Generation IV International Forum (GIF) for many years and is one of the driving forces behind the further development of the HTR reactor line. A lot of money was made available by the state for this. Due to the backlog in HTR development, the construction of HTRs can only have a medium-term perspective at best. Even the supposedly progressive former US Vice President and self-proclaimed climate protection guru Al Gore did not express himself unfriendly to the THTR in his latest book "We Have the Choice".

Obviously, Obama and Al Gore are not stupid. Of course they know about the energy policy flops of the past in their own country. But they too have to satisfy the corporations' energy policy wishes. Already 20 years before (!) The failure of the THTR in Hamm-Uentrop, the catastrophic failure of the entire reactor line was already exercised in a striking way through the construction of the high-temperature reactors! With the research reactor Peach Bottom-1 and the HTR prototype Fort St. Vrain.

***

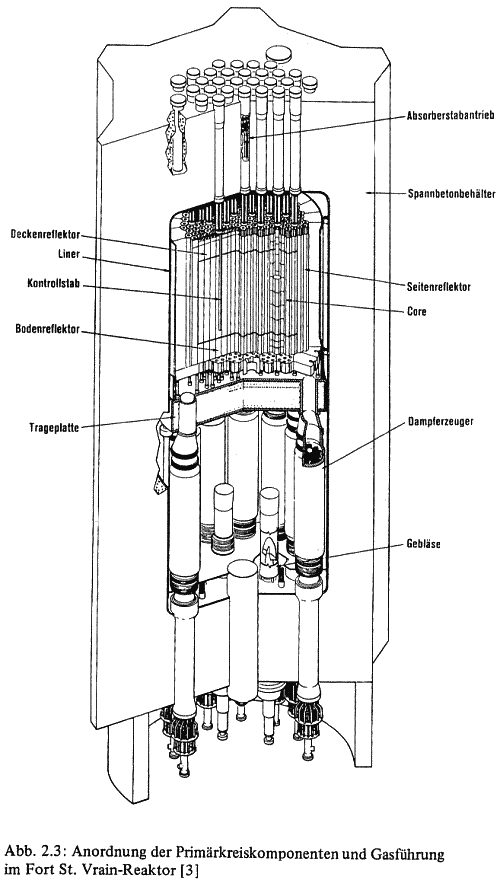

Fort St. Vrain: Mostly a standstill

Similar to the THTR in Hamm, the construction time for the Fort St. Vrain (FSV) reactor was very long. No spherical fuel elements were used in it, but block elements. The Ökoinstitut Freiburg reported in 1986: "The FSV-HTR was put into operation in 1976 after 11 years of construction and has not been operated continuously at full load since Once again, serious errors occurred, e.g. 1985 shut-off rods were not retracted for 'unknown' reasons. In addition, stress corrosion cracks were found in the control rod cables, etc. " (6)

The scientists from Darmstadt added: "Almost from the beginning, the FSV was not allowed to run more than 70% of the full capacity due to gas fluctuations in the reactor core and problems with the cooling fan as well as uncertainties with the guaranteed residual heat removal capacity. In addition, there was a leak in the steam generator as well a whole series of additional problems. For example, from the start of operation until 1981, the system only achieved an average work availability of 1988%. " (14,5)

Even Werner von Lensa (Vice President of the European High Temperature Reactor Technology Network) cannot avoid admitting the problems in Fort St. Vrain in his presentation under "Experiences" today:

"- Cavitation (" hollowing out ", HB) of the water pumps = one year delay

- Leaks in He fan bearings = further delays

- Error on (reserve) shut-off rods

- Bypass of hot helium and corrosion on shut-off rod drives

- Fluctuation of the core flow = 70% performance

- Liner leaks on core support "(4)

*

250 employees were evacuated ...

All of this is nothing compared to what Holger Strohm researched in his bestseller "Peaceful in the Catastrophe": "The Americans had high hopes and a lot of money in the development of high-temperature reactors. With the construction of the Fort St. Vrain demonstration reactor The Americans also got a head start of 300 MWel in 1973. However, several tons of water penetrated the core at the beginning of 1975, so that the reactor stood still for several years It named a major or medium leak in the reheater and a failure of the external power supply as possible main causes of major accidents.

In January 1978 another accident occurred with the American high-temperature reactor. At the request of MP Zywietz (FDP), the federal government informed the Bundestag: "In the Fort St. Vrain nuclear power plant, the Public Service of Colorado, which is equipped with a helium-cooled high-temperature reactor, was opened on January 23, 1978 around 11.30 a.m. (US East Coast Time) Failure of the spindle seal of a valve Helium, which was permeated with radioactive iodine, was released into the reactor building ... As a result of emergency plans, 250 employees were evacuated to the information center opposite the facility and the surrounding streets were cordoned off in Jülich ... "(5)

Greenpeace also reported another incident on October 3, 1987: "Fort St. Vrain nuclear power plant in Colorado: Leaking oil triggers a fire in the turbine area. Control room lines, valves and instruments are severely damaged." (6)

*

Decline of a reactor line

Ulrich Kirchner describes the decline of this reactor line in the USA in his standard work "The High Temperature Reactor" as follows: "In 1974 and 1975 the energy supply companies in the USA withdrew all options for high-temperature reactors for various reasons. Technical decisions played a special role in these decisions Problems and incidents with the Fort St. Vrain reactor, the successful commissioning of which was considered a 'conditio sine qua non' (condition, HB) for the American market launch.In the summer of 1989, the operating company decided that the reactor should not continue to operate, although an operating time up to the year 2008 was planned. " (7)

Fort St. Vrain was demolished by 1992 and thus came to an inglorious end. The American nuclear industry struggled and embarrassed itself with Peach Bottom-1 and FSV for a full 1962 years between 1992 and 30. But none of that counts. Industry has its wishes and the government officials who depend on it have them to fulfill. That is why Barack Obama is now spending billions of dollars on the continuation of a nuclear adventure, the outcome of which is foreseeable.

Horst Blume

Notes:

- BusinessDay from March 30, 3

- Ökoinstitut Freiburg (Frey, Fritsche, Herbert, Kohler): "The thorium high-temperature reactor in Hamm and the planned high-temperature reactor variants", page 19

- Ökoinstitut Darmstadt, see under 2, pages 2 - 4

- Werner Lensa, "International Development Programs for High-Temperature Reactors", sheet 33

- Holger Strohm: "Peaceful in the catastrophe", 1981, page 789; Small correction to the book entry: The water ingress took place in 1975, not 1973.

- Greenpeace

- Ulrich Kirchner: "The high-temperature reactor. Conflicts, interests, decisions", 1991, page 120

FORT ST. VRAIN UPDATE

Presented By O.R.Lee

1985 Utility / User Conference on the HTGR

Introduction

Last year when I spoke to you, I described a plant upset which occurred in June, and involved six pairs of control rods not automatically inserting by gravity into the core as required upon receipt of a reactor shutdown signal.

We initiated actions to identify the cause of the event, clean up the six control rod drive assemblies, and anticipated returning the plan back to operation in September.

However, the discovery of stress corrosion cracking in the control rod drive cables and boric acid crystallization on the reserve shutdown material, as well as the lack of a definite failure mechanism being identified for the six control rods which did not insert into the core led to the decision to refurbish all of the control rod drive units and restore them to a "like new" condition.

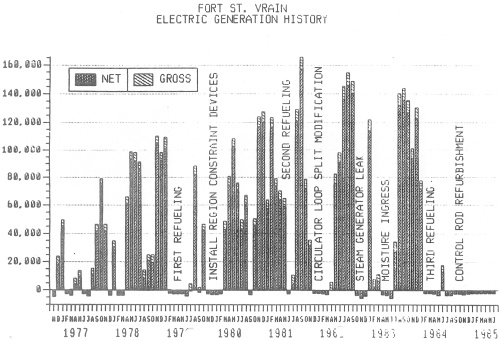

This major undertaking, coupled with the discovery of a bearing water to interspace leak on one of the four helium circulators and subsequent disclosure of stress corrosion cracking in the holddown bolting of that circulator, extended the shutdown, and resulted in an unprecedented rework effort in the history of Fort St Vrain. Consequently, the generator has remained off line for the last twelve months, reversing the upward trend we saw last year.

(Place Fort St. Vrain Electric Generation Graph on Screen and Discuss "Trend")

Operations

When we met a year ago, I reported to you that Fort St. Vrain had completed its third refueling, and the plant was restarted during the second week of June and brought to approximately 60% power until a plant upset on June 23rd terminated operations.

I will elaborate on the control rod drive rework effort, and describe other problems we encountered and resolved during this unique period.

Subsequent to the June 23rd event, we initiated actions to identify the root cause of the failure and restore the deficient control rods to an operable status. The six control rods that failed to insert were the first to be examined and rebuilt with additional control rods being examined and rebuilt afterwards. No definite cause of the failure could be identified, but indications were that shim motor bearing wear and debris buildup, which was the primary contributor.

During the course of our efforts, several other problems unrelated to the control rod failure were also identified.

One problem involved control rod instrumentation anomalies which began manifesting themselves, apparently induced by the high moisture content in the primary coolant.

Another consisted of a control rod absorber string suspension cable failure. 'The cable was evaluated, and stress corrosion cracking was identified as the failure mechanism.

The third problem was discovered during a test of a control rod drive reserve shutdown hopper. Test results revealed that only 30 to 40 of the 80 pounds (nominal) of reserve shutdown material was expelled when the hopper was actuated. Inspection and chemical analysis of the material remaining in the hopper revealed boric oxide crystallization which facilitated bridging of the boron balls inside the hopper.

In order to implement a fix which would prevent a recurrence of the failures and problems encountered, the rigorous control rod drive refurbishment program began on February 22, 1985, and included:

- Refurbishment of all shim motors, orifice drives, and gear trains and replacement of all motor bearings with new bearings,

- Replacement of all control rod instrumentation with new components, all stainless steel suspension cables with Inconel cables, and miscellaneous components with like components made from materials not as susceptible to chloride stress corrosion.

- Replacement of all reserve shutdown material with material which significantly reduces the amount of impurities available for conversion to boric acid crystals,

- Installation of temperature monitoring devices, and purge seals designed to inhibit primary coolant from entering the gear train and motor area.

The control rod drive refurbishment program was completed on June 24, 1985. Thirty-seven control rod drives have been completely refurbished and are in the reactor.

In September, 1984, moisture was found in a circulator penetration interspace. The carrier was determined to be a bearing water leak from one of the helium circulators to the interspace. This necessitated removal of the circulator for repair.

During the refurbishment of the circulator, stress corrosion cracking was discovered on the holddown bolting. The stainless steel bolting was replaced with inconel bolting, and preparations were made for removal of the remaining three circulators to accomplish the bolting change-out.

By June, 1985, all four helium circulators had undergone the necessary bolting change-out and were reinstalled into the reactor.

In July, the NRC advised us that Fort St. Vrain could be restarted. Although we are limited to power levels less than 15 percent of rated thermal power, we are pursuing NRC authorization to operate at full rated power.

Regulatory Developments

Last year, I noted that there had been a distinct increase in regulatory involvement on both the state and federal level. That involvement is even more pronounced this year, and I would like to share with you our initiatives in dealing with selected issues.

- Last October, we received an NRC Assessment Report which contained a requirement that we use a third party consulting group to review our management structure and practices. To comply with this requirement, a consultant was hired to perform an analysis of the overall conduct of operations at Fort St. Vrain. After receiving the consultant's evaluation and recommendations, we took a number of important actions to deal with the issues raised in the consultant's report and in the earlier NRC Assessment Report. First of all, we carried out a major reorganization under which I now report directly to the President of our Company. To help conserve my time, we consolidated all fossil production activities under a new general manager position reporting directly to me. To improve our interaction with the NRC, we established a senior management communication link to the NRC.

- In response to the consultant's recommendations and to address NRC concerns, we have established a Performance Enhancement Program. As part of that program, we have identified six major projects with many sub-projects, through which we intend to:

1) Resolve organizational concerns.

2) Establish a master planning and scheduling function for planned projects.

3) Incorporate a planning and scheduling function within the existing preventive maintenance function.

4) Upgrade nuclear policies and procedures, including the commitment control program.

5) Improve management and nuclear personnel training.

6) Improve the plant conduct of operations, particularly the NRC's observation regarding our failure to follow procedures.

These projects represent a major effort on our part to ensure that Fort St Vrain achieves a consistent standard of excellence.

- Since 1979, we have submitted environmental qualification information to the NRC. We based these submittals on our understanding of 'how the regulations dealing with the environmental qualification of, safety-related V electrical equipment should be applied to a high temperature gas cooled reactor. Throughout this period, the NRC provided very little feedback. In January, 1985, we received a letter from the NRC requesting additional information to determine the extent of our compliance with the regulations. After numerous discussions, meetings, and exchanges of correspondence, we have been advised by the NRC that there are deficiencies in our program and that we will not be allowed to go to full power operation until we can demonstrate conformance to the applicable regulations. This NRC position, in effect, could disallow the qualification of all electrical equipment installed in a harsh environment at Fort St. Vrain. We have various studies and tests in progress, and are vigorously pursuing a resolution to this matter.

- Last year, I told you about a Colorado PUC decision under which we would be penalized for inadequate Fort St. Vrain performance by shifting excess costs of power production at Fort St. Vrain from the ratepayers to our shareholders. The potential refund under this order, which increases quite dramatically as long as Fort St. Vrain is nonoperational, was responsible for A $ 10.9 million charge against pretax income for the first six months of 1985. Although the Denver District Court issued an order setting aside the Colorado PUC decision, the matter has now been appealed to the State Supreme Court.

Radiological

Once again, Fort St. Vrain topped the rest of the worldwide nuclear power industry with its exceptionally low personnel radiological exposure. The total exposure received by Fort St. Vrain personnel in 1984 was 3.11 person rem. This represents an increase from 0.95 person rem received in 1983, but is still well below the industry average for Light Water Reactors. This graph depicts the comparison of exposures for PWR's, BWR's, and Fort St. Vrain throughout this period.

The increase in 1984 at Fort St. Vrain is attributable to control rod drive maintenance and pre-refurbishment work, recognizing that the formal control rod drive refurbishment program was not until begun early in 1985.

conclusions

We have encountered adversitles in the past. He are presently involved in a major evolution regarding environmental qualifications of equipment. We will undoubtedly be faced with other equally challenging problems in the future. Nevertheless, Public Service Company remains committed to Fort St. Vrain and to the technology and experience it can contribute to the nuclear industry.

For work on 'THTR circular', 'reaktorpleite.de' and 'Map of the nuclear world' we need up-to-date information, energetic, fresh comrades-in-arms under 100 (;-) and donations. If you can help, please send a message to: info@reaktorpleite.de

Donation appeal

- The THTR circular is published by the 'BI Environmental Protection Hamm' and is financed by donations.

- The THTR circular has meanwhile become a much-noticed information medium. However, there are ongoing costs due to the expansion of the website and the printing of additional information sheets.

- The THTR circular researches and reports in detail. In order for us to be able to do that, we depend on donations. We are happy about every donation!

Donations account: BI Umweltschutz Hamm

Usage: THTR Rundbrief

IBAN: DE31 4105 0095 0000 0394 79

BIC: WELADED1HAM

***